Cenlub Systems

We take pride in being one of the pioneers in Centralized Lubrication Systems in India. Established in 1990, Cenlub Systems have been growing year on year expanding the product range, models and applications. Continuous quality improvement is a part of the company culture and runs in the blood of every company employee. We are the only Indian company to have such a diverse range of products. Developing products as per customer requirement and application is one of our major strengths and this ensures that our customers get exactly what they are looking for. We cater to a number of industries like machine tools, plastic processing, material handling, printing and packaging, sugar, mining, construction, steel, etc.

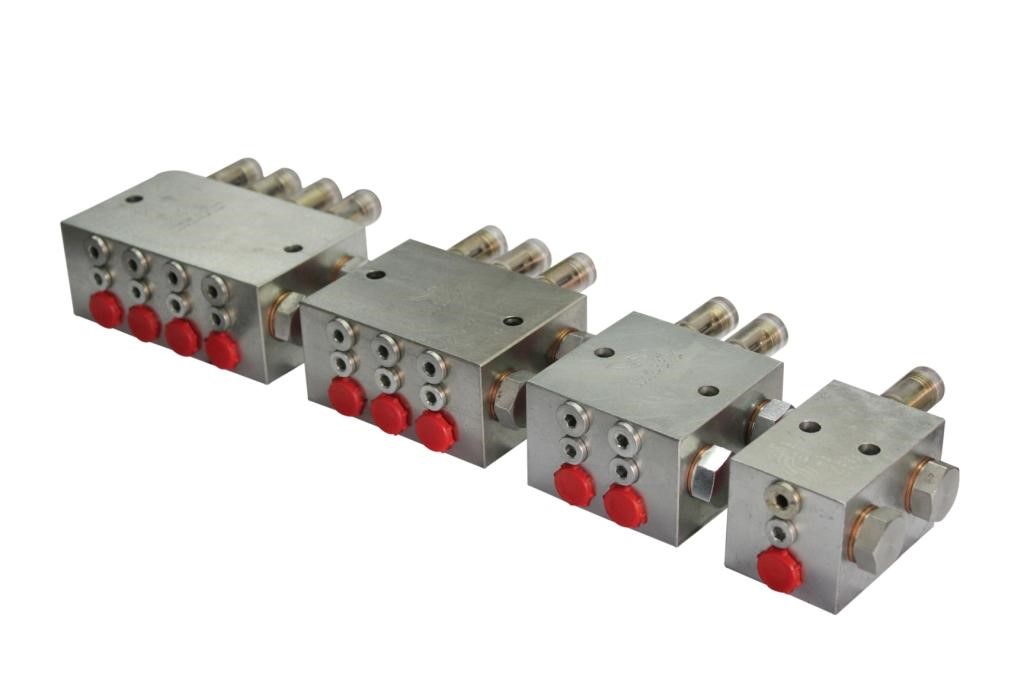

LUBRICATION DISTRIBUTOR

Lubrication Distributors primary job is to ensure delivery of metered quantity of lubricant to the lube points irrespective of the backpressure. We offer a variety of distributors depending on lubricant, type of system, dose, feedback mechanism and application...

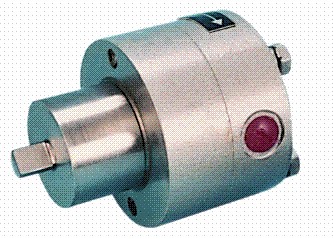

LUBRICATION PUMPS

Pump is the heart of any centralized lubrication system and its purpose is to deliver lubricant at desired flow rate and pressure. Pump models vary with lubricant, capacity, pressure rating, drive, type of system and application...

SPECIALIZED LUBRICATORS

These are specific lubricators designed typically for certain special applications. For eg. sheet metal lubrication before stamping process, toffee machine lubrication, etc...

TIMERS & CONTROLLERS

Timers & Controllers are the mind of any automatic lubrication system. They define the frequency and the quantity of lubrication. They also capture feedback from the system and indicate healthiness of the system. Custom-made panels are also designed and manufactured in case of larger and customized systems...

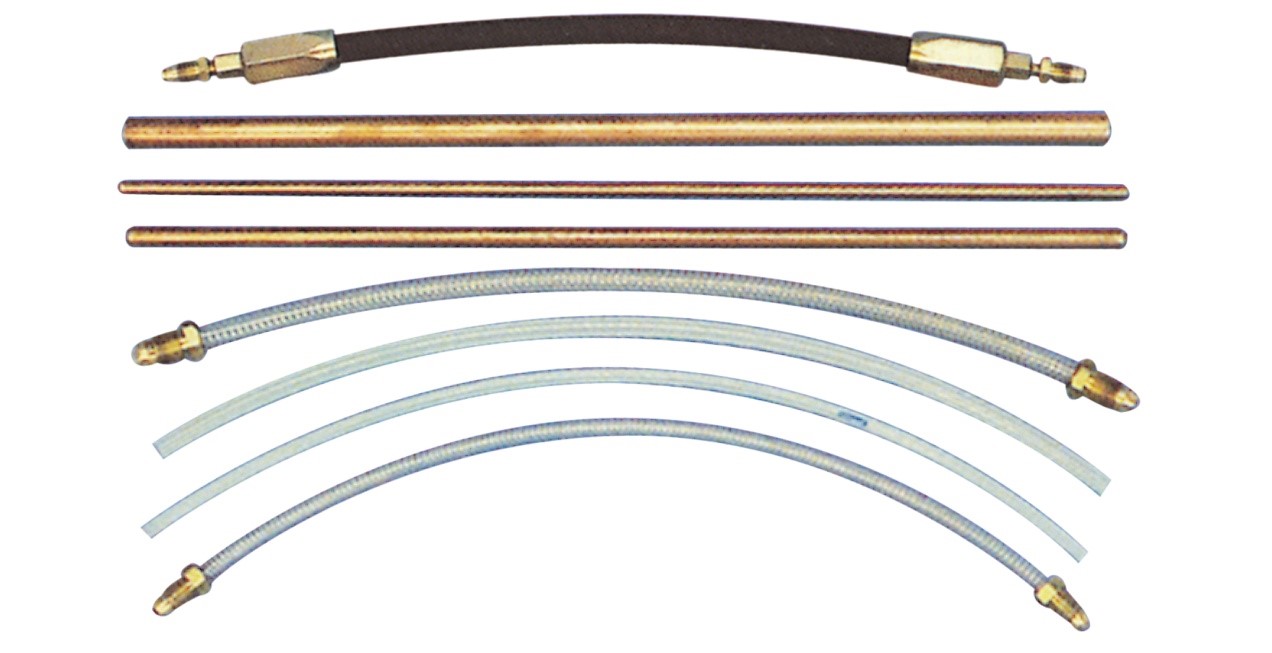

TUBES, HOSES, PIPES, FITTINGS AND CLAMPS

Tubes, Hoses, Pipes, Fittings and Clamps act as arteries and veins of the lubrication system carrying pumped lubricant under pressure to distributors and subsequently to lube points and in case of recirculation systems carrying back the return oil...

MOBILE LUBE VAN / MOBILE SERVICE VAN

We Manufacture Mobile Service Van as per customer’s requirement for providing service back up on field. These vans are usually equipped with a generator; compressor; welding machine; engine oil, transmission oil, coolant and grease pumps; tyre inflator; car washer and a workbench. For safety fire extinguishers are also provided. These vans can be designed and manufactured specifically as per customer requirement...